Quality Assurance

The company has meticulously established all necessary facilities for bearing manufacturing, equipped with advanced processing technology, a highly skilled and experienced workforce, and an ongoing personnel training program. We are committed to delivering superior product quality and performance through rigorous inspection and comprehensive documentation at each stage of production.

Each raw material is subjected to rigorous testing for chemical composition using a spectrophotometer, and its micro structure is carefully analyzed by a qualified metallurgist both before and after heat treatment.

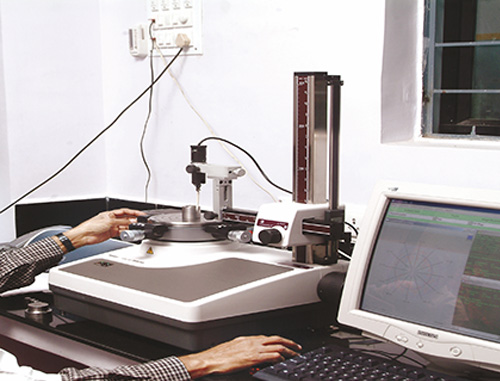

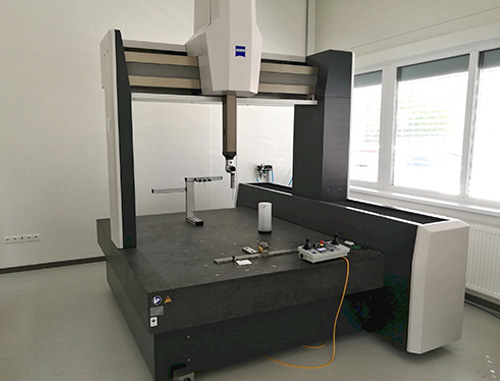

Surface roughness and roundness are precisely measured using state-of-the-art testers. We maintain detailed statistical records in full compliance with ISO and IATF 16949 standards. Additionally, the company proudly holds ISO 9001:2015 certification, granted by TUV SUD.

Our well-stocked and efficiently managed inventory enables us to promptly fulfill customer orders at highly competitive prices, all while ensuring the necessary certifications are in place.

We are dedicated to continuous improvement, consistently enhancing our manufacturing processes, testing procedures, and quality control systems to ensure the highest standards of excellence in every product we deliver.

Production Area

Surface Roughness Inspection

Microscope

Surface Roughness Inspection

Roundness Inspection

AOI Visual Inspection

CMM